HYBRICOOL®

New Cooling Technology

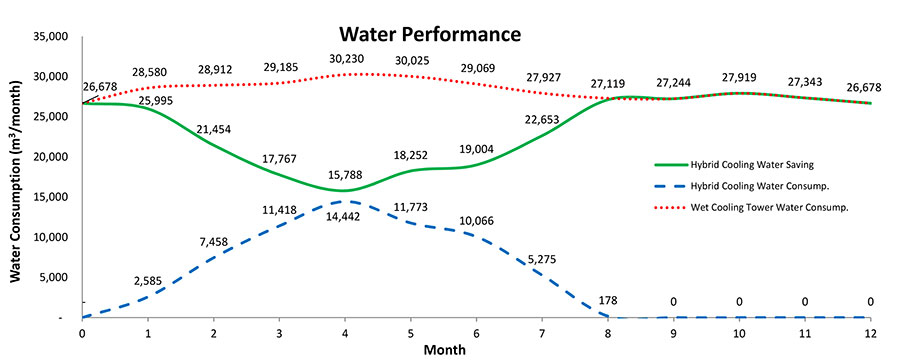

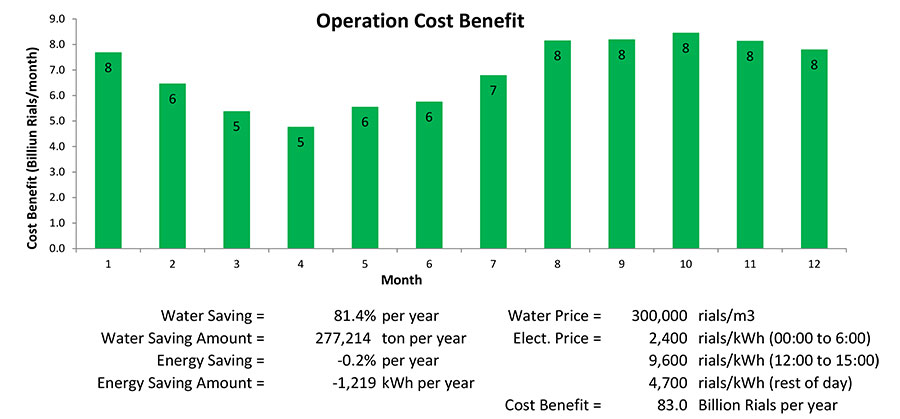

The hybrid cooling tower uses artificial intelligence and sensitive temperature and humidity sensors to save up to 90% water compared to the cooler system. The device’s upgraded system, called ICCW, is able to increase this saving to 100%.

PATENTED

Industrial Applications Of Cooling Tower

Industrial applications produce enormous amount of heat. Instead of wasting the water used for these purposes, cooling towers cool the water repeatedly and make it suitable for reuse. Depending on the industry and the kind of cooling needs of a plant, Artech can provide small as well as big cooling towers. Some of them can be easily assembled in the plant, eliminating any hassle of transporting large and bulky towers.

Let’s take a look at certain areas where cooling towers are widely used.

- Paper Manufacturing

- Plastic Manufacturing

- Rubber Manufacturing

- and Processing

- Industries

- Steel Plants

- Metal Casting and Metal

- Forging Plants

- Rolling Mills

- Paints Industry

- Textile Manufacturing

- Industry

- Vehicle Manufacturing

- Industry

- Ceramic Tiles Industry

- Glass Manufacturing Industry

Petrochemical plants

Chemical plants

Chemical plants

Power plants

Pharmaceutical industry

Petroleum refineries

New Cooling Technology

HYBRICOOL®

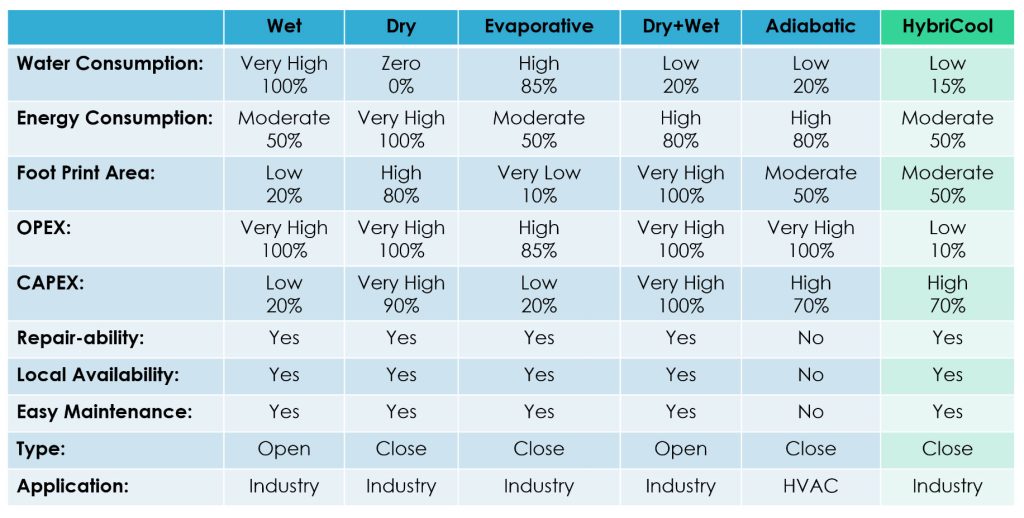

A Hybrid Cooler is an integrated technology of Adiabatic Cooler and Evaporative Cooler. This advanced technology helps you when required cooled water temperature is very lower than arid hot climate air.

Advantages:

- Low maintenance and operational cost

- Applicable for arid and hot climate with cooled water temperature very lower than air temperature

- Fully closed circuit running, no process water consumption

- Up to 90% water saving in comparison with wet cooling tower

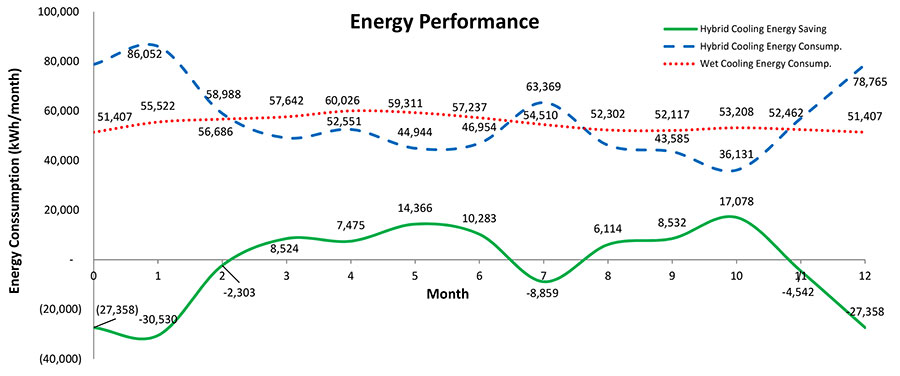

- Low energy consumption in comparison with Air cooler

- Easy operation

- Custom design

- Applicable for small to very large units

- Lower foot print area rather than Wet cooling tower and Air cooler

Disadvantages:

- Higher capital cost rather than Wet cooling tower

Applications:

- Oil, Gas, Petrochemical Plants

- Power plants

- Food and Beverage Plants

- Mining, Smelting, and Metal hot forming Plants

- Chemical & Pharmacological Plants

Key Features:

- Solid construction featuring full enclosures that surround heat exchanger cores to optimize air flow

- Multi-row and bare tube bundle heat exchangers cores for maximum heat transfer capacity

- Tailor designed Turbulator that increases heat transfer by up to 300% over Air Cooler

what our clients say